Digital Driver

Model DM556EU

Digital Technology, 50 VDC/ 5.6 A

Download data sheet

Download data sheet Download user manual

Download user manual Comparison DM556/ DM556EU/ EM556S

Comparison DM556/ DM556EU/ EM556S

The DM556EU is a digital stepper drive with simple design and easy setup. By implementing Leadshine’s advanced stepper control technology, this stepper drive is able to power 2 phase and 4 phase stepper motors smoothly with optimal torque and low motor heating & noise. Its operating voltage is 20 - 50 VDC and it can output up to 4.2 A current.

All the micro step and output current are done via DIP switches. Therefore, the DM542EU is an ideal choice for applications requiring simple step & direction control of NEMA 23, 24, and 34 stepper motors.

- Anti-Resonance for optimal torque, extra smooth motion, low motor heating and noise

- Motor auto-identification and parameter auto-configuration for optimal torque for a wide range of motors

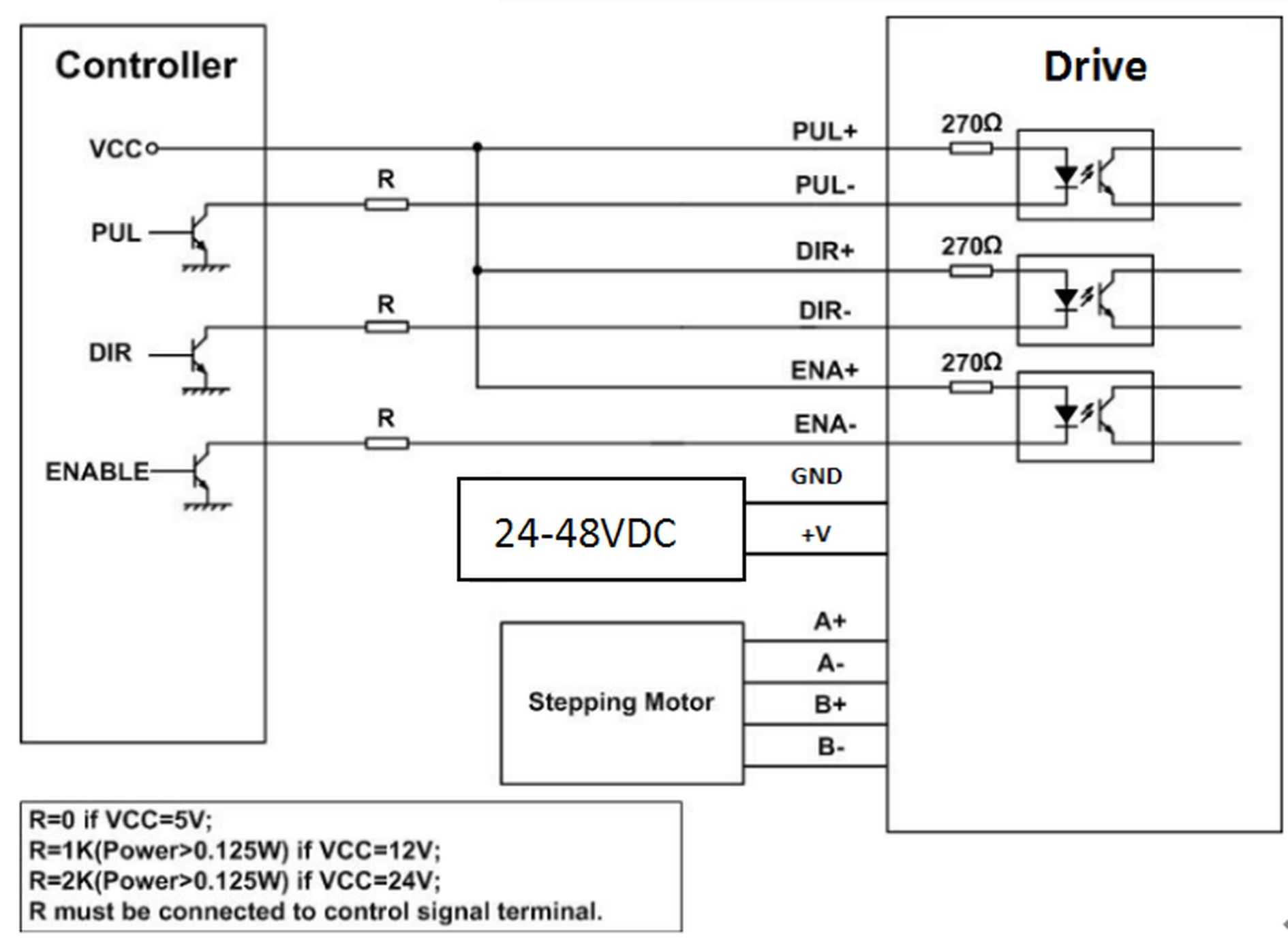

- Step & direction (PUL/ DIR) control

- Multi-Stepping for smooth motor movement

- Optically isolated inputs

- Input voltage 20 – 50 V DC

- 16 selectable micro-step resolutions of 400 - 25,600 via DIP switches

- 8 selectable output current settings of 1.8 - 5.6 A via DIP switches

- Smooth motor start-up without “jump”

- Pulse input frequency up to 200 kHz

- Automatic idle-current reduction

- Protections for over-voltage and over-current

| Parameters | Min | Typ. | Max | Unit |

| Output current | 1.8 | - | 5.6 (4.0 RMS) | A |

| Supply voltage | 20 | 24 - 48 | 50 | VDC |

| Logic signal current | 7 | 10 | 16 | mA |

| Pulse input frequency | 0 | - | 200 | kHz |

| Minimal pulse width | 2.5 | - | - | µs |

| Minimal direction setup | 5.0 | - | - | µs |

| Insulation resistance | 500 | MΩ |

| Parameters | Min | Typ. | Max |

| Microsteps/ 1,8 ° | 400 | 25,600 | |

| Pulse/ Direction (PUL/ DIR) | X | ||

| NEMA sizes | 23 | 34 | |

| Motor type Mecheltron | 57BYGH-XXXX | 86BYGH-XXXX |

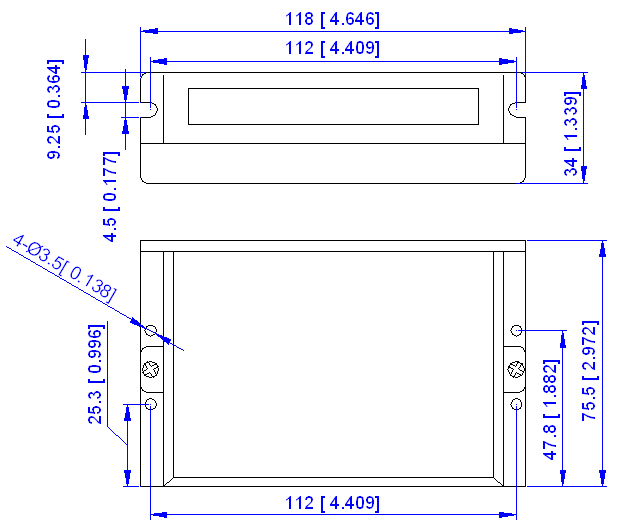

Unit: mm [inch]

Suitable for a wide range of stepper motors of NEMA sizes 23, 24 and 34 (57 x 57 mm to 86 x 86 mm). It can be used in various kinds of machines, such as X-Y tables, engraving machines, labelling machines, laser cutters, pick-place devices, and so on. Particularly well suited for applications where low noise levels, less heat development, high speed and high precision are desired.

A typical system consists of stepper motor, stepper motor driver, power supply and controller.

The following image shows a typical connection schematic: