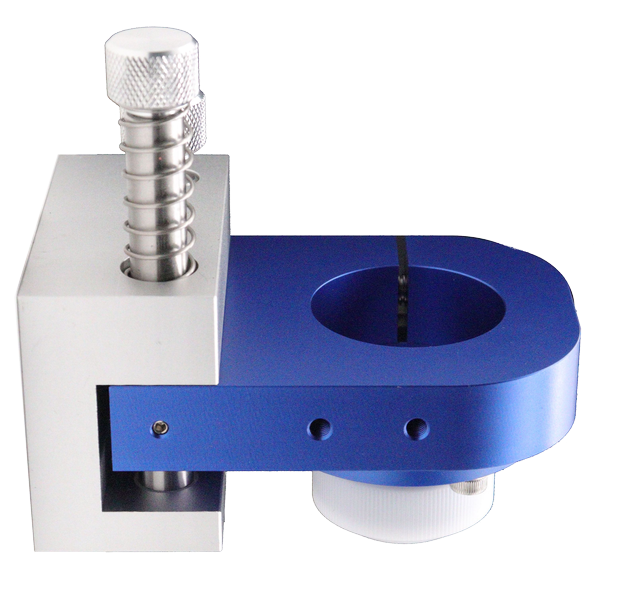

Floating Engraving Stop

Download data sheet

Download data sheetFeatures:

|

Description:

The pressure of the engraving depth regulator is regulated by a spring. This results in a constant contact pressure of the milling tool. Thanks to a partially open cap made of POM, the device glides smoothly over all materials without damaging their surface. The engraving depth regulator thus ensures uniform engraving or constant machining depth for all engraving work and e.g. for the production of circuit boards, regardless of fluctuating material thickness or variations in the evenness of the base.

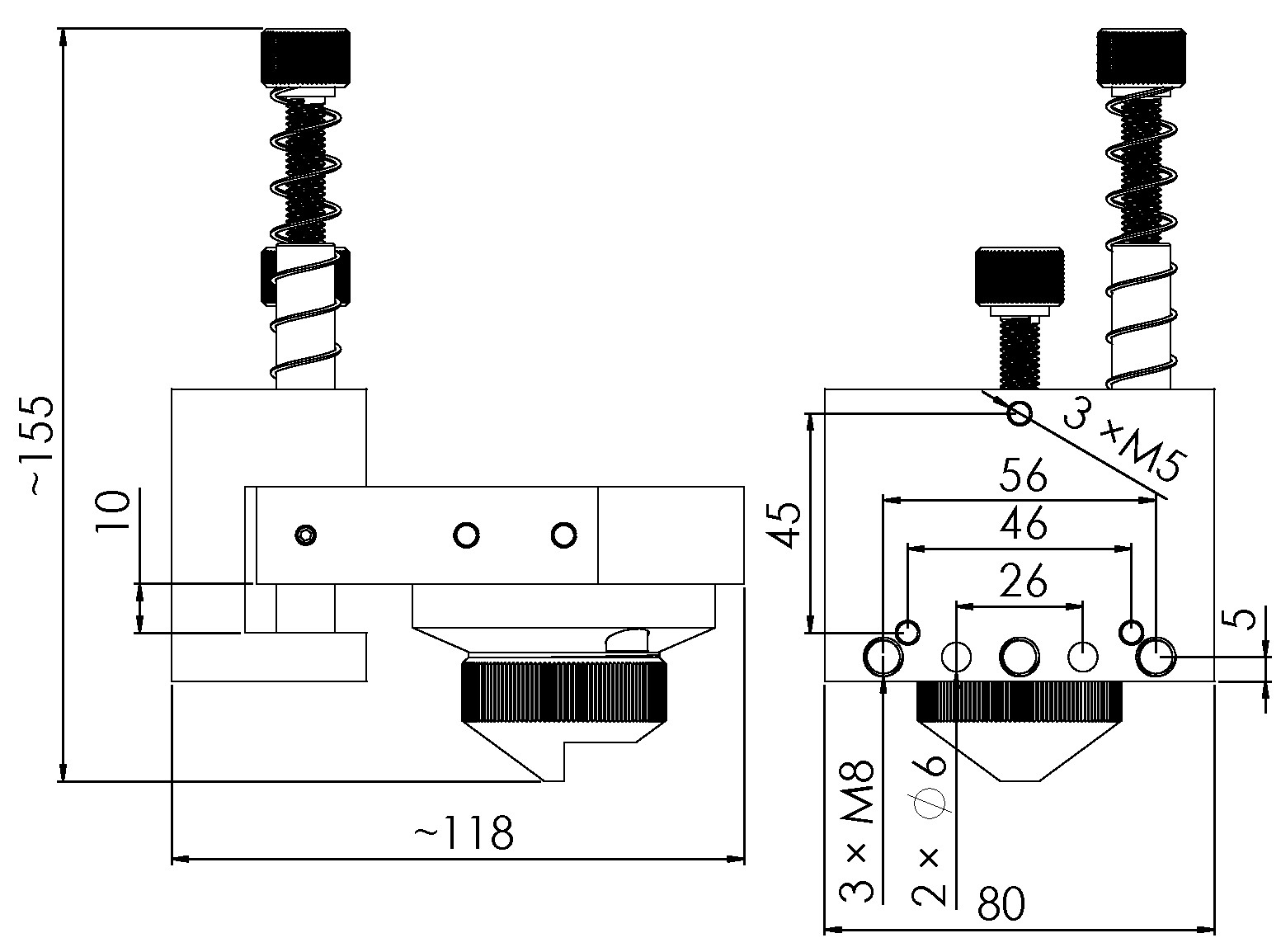

Technical Data:

|

Scope of delivery:

- 1 Piece Floating Engraving Stop, preassembled

- Sturdy practical storage box

- Weight (incl. Packing) ~1070 g

Accessories:

- Optional POM sliding cap with Ø 42 mm contact surface for large-area contact pressure on the material to be machined

English