Integrated AC Servo Motors

iHSV57

Download data sheet

Download data sheet Download parameterization software

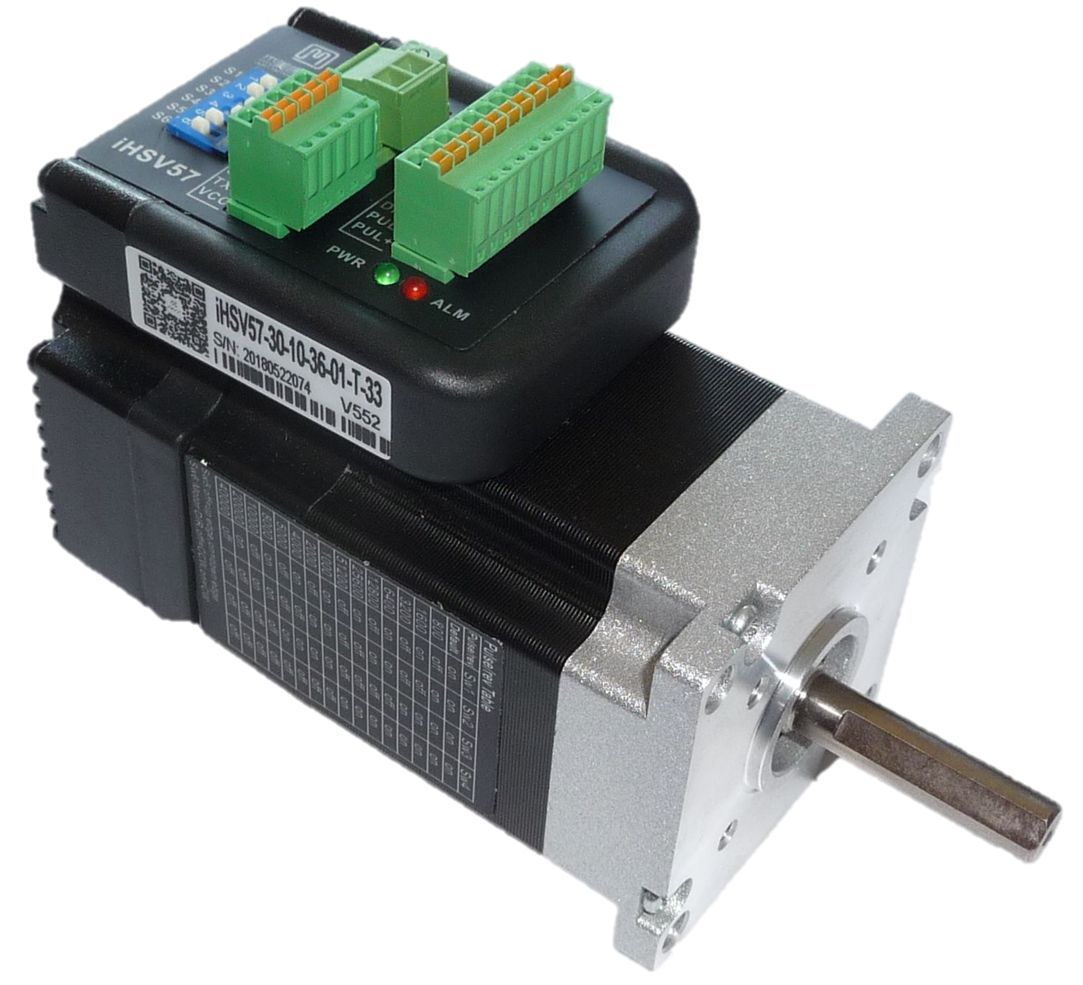

Download parameterization softwareiHSV57-XX Integrated AC Servo Driving Motor is a perfectly integrated AC servo drive into a servo motor, adopts vector control in DSP chip, features in low cost, full closed loop, all digital, low heat, small vibration, and high response, as well as includes three adjustable feedback loop control modes (position loop, speed loop, and current loop). iHSV57-XX are a series of stable performance, high cost-effective motion control products.

- High positioning accuracy

- High torque

- Cost-effective high speed response

- Smooth and very low noise

- Compact size

- Pulse Input Mode Pulse + Direction

- Current Loop Bandwidth:(-3dB)2KHz (Typical)

- Speed Loop Bandwidth: 500Hz (Typical)

- Position Loop Bandwidth: 200Hz (Typical)

- Parameters to download via RS232 to PC.

- Users can define subdivisions via external Dial-up switches or via software.

- Over-current, I2T-motor-current-observation, Over-voltage, Under-voltage, Over-heat, Over-speed, protections.

iHSV57-XX can be used in various applications such as laser cutters, laser markers, high precision X-Y tables, labeling machines, CNC router, etc. Its unique features make the iHSV57-XX an ideal choice for applications that require low-speed smoothness and high torque at higher revolution by small mounting space.

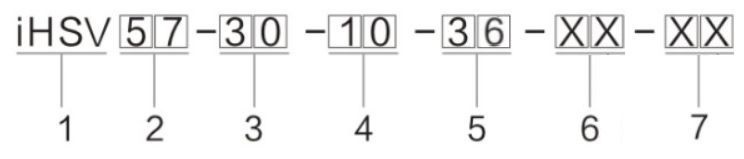

iHSS stepper:

- 1. Integrated Servo motor

- 2. Motor frame size: 57

- 3. Motor revolution (unit: x 100 RPM) 10 ≙ 1000 RPM, 20 ≙ 2000 RPM, 30 ≙ 3000 RPM

- 4. Output Power (unit: x 10 W) 10 ≙ 100 W; 20 ≙ 200 W

- 5. Motor rated DC voltage: 24 means voltage is 24 V, 36 means voltage is 36 V.

- 6. Shaft length: 01 = 30 mm, 21 = 21 mm

- 7. Pilot diameter: No digit = 25.4 mm, 38 = 38.1 mm

|

Parameters: |

Min |

Typical |

Max |

Unit |

|

Input Voltage |

20 |

36 |

50 |

VDC |

|

Continuous output current |

6 |

A |

||

|

Pulse per revolution |

4 |

- |

51200 |

- |

|

Pulse input frequency |

- |

200 |

kHz |

|

|

Pulse Voltage |

3.3 |

5 |

24 (with R 3 - 5 kΩ) |

V |

|

Logic Signal Current |

7 |

10 |

16 |

mA |

|

Isolation Resistance |

100 |

- |

- |

MΩ |

|

Part Name: |

iHSV57-30- 10-36-21-38 iHSV57-30- 10-36-01 |

iHSV57-30- 14-36-21-38 iHSV57-30- 14-36-01 |

iHSV57-30- 18-36-21-38 iHSV57-30- 18-36-01 |

Unit |

|

Rated Power |

90 |

140 |

180 |

W |

|

Rated Torque |

0.29 |

0.44 |

0.57 |

Nm |

|

Rated Speed |

3000 |

3000 |

3000 |

1/min |

|

Max. Speed |

3000 |

3000 |

3000 |

1/min |

|

Rated Voltage |

36 |

36 |

36 |

V |

|

Weight |

1.0 |

1.3 |

1.6 |

kg |

| Cooling |

Natural cooling or forced air cooling |

|

|

Operating Environment |

Environment |

Avoid dust, oil, fog and corrosive gases |

|

Ambient Temperature |

0 ℃ - 40 ℃ |

|

|

Humidity |

40 %RH - 90 %RH |

|

|

Operating Temperature |

70 ℃ max |

|

| Storage Temperature |

-20 ℃ - 80 ℃ |

|

|

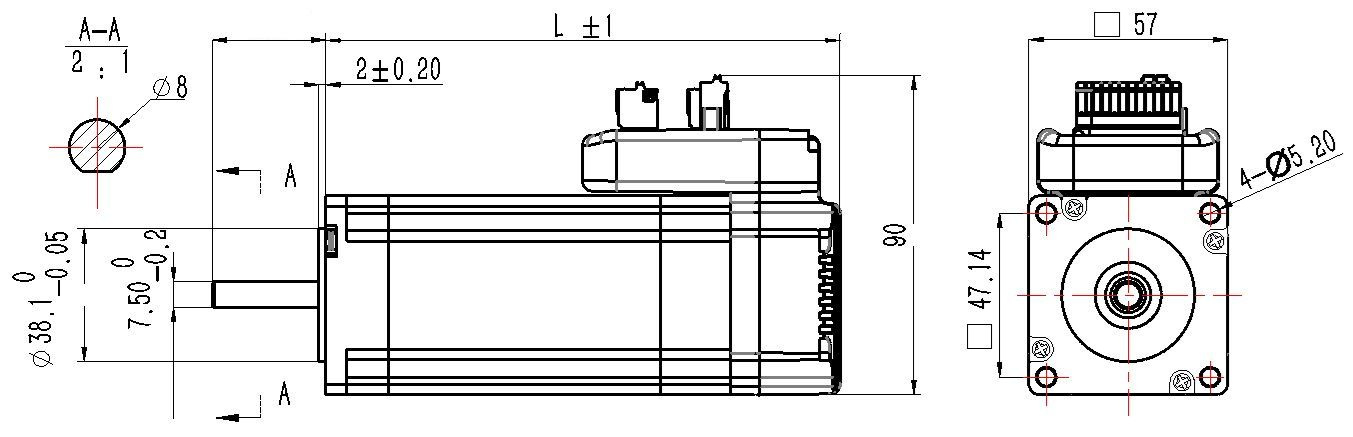

Name: |

Motor length |

Length of motor and drive (L) |

Shaft length |

Pilot diameter |

|

iHSV57-30-10-36-21-38 |

76 mm |

110 mm |

21 ±1 mm |

38,1 mm |

|

iHSV57-30-14-36-21-38 |

96 mm |

130 mm |

21 ±1 mm |

38,1 mm |

|

iHSV57-30-18-36-21-38 |

116 mm |

150 mm |

21 ±1 mm |

38,1 mm |

|

iHSV57-30-10-36-01 |

76 mm |

110 mm |

30 ±1 mm |

25,4 mm |

|

iHSV57-30-14-36-01 |

96 mm |

130 mm |

30 ±1 mm |

25,4 mm |

|

iHSV57-30-18-36-01 |

116 mm |

150 mm |

30 ±1 mm |

25,4 mm |

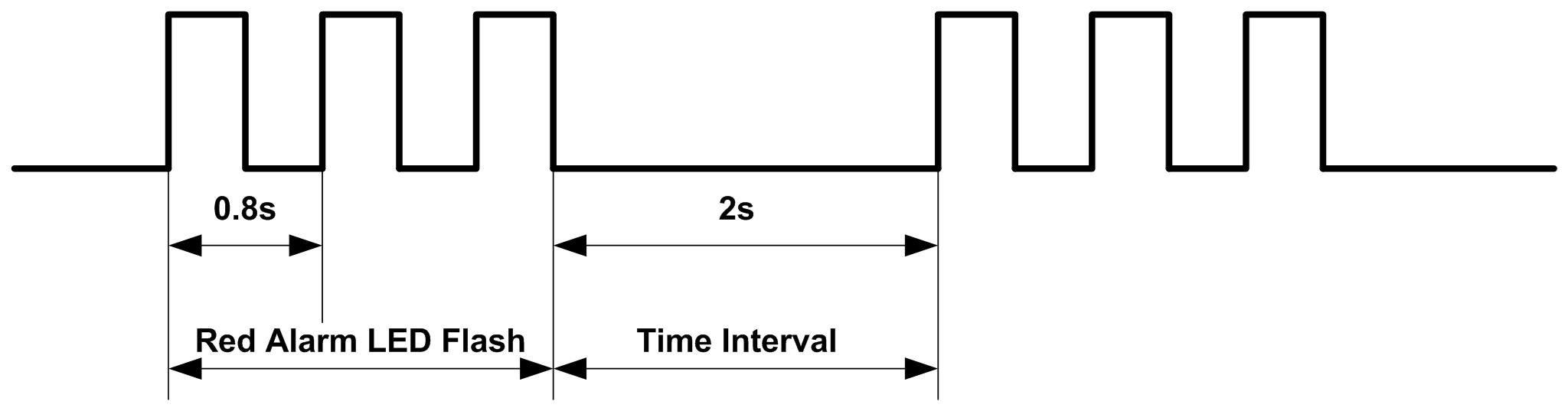

| LED light flashes | Alarm description |

| 2 times | Drive over current |

| 3 times | Driver position deviation exceeds set value |

| 4 times | Driver encoder alarm |

| 7 times | Driver overload |

The iHSSXX have three connectors, one connector for power connections, another one for control signal connections and a third one for RS232 communication connections

|

Power Connector +VDC

|

|||

| Pin | Name | I/O | Description |

| 1 | DC+ | I | Power Supply Input (Positive) 20 – 50 VDC; 36 V is typical. Recommended to leave reasonable reserve for voltage fluctuation and back-EMF during deceleration. |

| 2 | GND | GND | Power Ground (Negative) |

|

Control Signal Connector |

|||

|

Pin |

Name |

I/O |

Description |

|

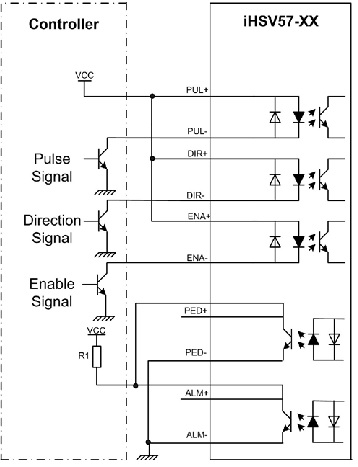

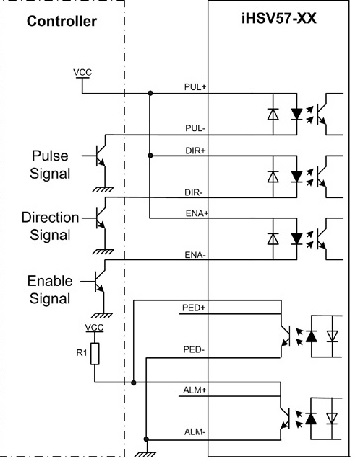

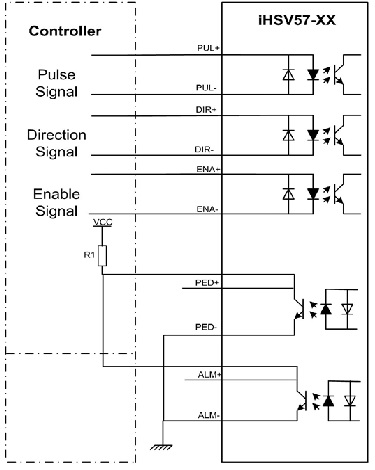

1 |

ALM- |

O |

Alarm Signal: OC output signal, activated when one of the following protection is activated: over-voltage and over current error. They can sink or source MAX 8 mA current at 24 V, respectively 200 mW. The impedance between ALM+ and ALM- is high for normal operation and becomes low when any protection is activated. |

|

2 |

ALM+ |

O |

|

|

3 |

PED- |

O |

In-position Signal: In-position Signal: OC output signal, activated when actual motor position reaches to target position. This port can sink or source MAX 8 mA current at 24 V, respectively 200 mW. The impedance between PED+ and PED- is high for normal operation and becomes low when the target position is reached. |

|

4 |

PED+ |

O |

|

|

5 |

ENA- |

I |

Enable signal: This signal is used for enabling/disabling the drive board. By default, high level (NPN control signal) for enabling the drive board and low level for disabling the drive board. It is usually left UNCONNECTED (ENABLED). Please note that the PNP and Differential control signals are on the contrary, namely Low level for enabling. |

|

6 |

ENA+ |

I |

|

|

7 |

DIR- |

I |

Direction Signal: In single-pulse mode, this signal has low/high voltage levels, representing two directions of motor rotation For reliable motion response, DIR signal should be ahead of PUL signal by 5μs at least. 3.5-24V for DIR-HIGH, 0-0.5V for DIR-LOW. Toggle DIP switch S6 to reverse motion direction. |

|

8 |

DIR+ |

I |

|

|

9 |

PUL- |

I |

Pulse Signal: In single pulse (pulse/direction) mode, this input represents pulse signal, active at each rising or falling edge (Software configurable). 3.5 – 24 V for PUL-HIGH, 0 - 0.5 V for PUL-LOW. For reliable response, pulse width should be longer than 2.5μs for 200kHz MAX input frequency. |

|

10 |

PUL+ |

I |

|

|

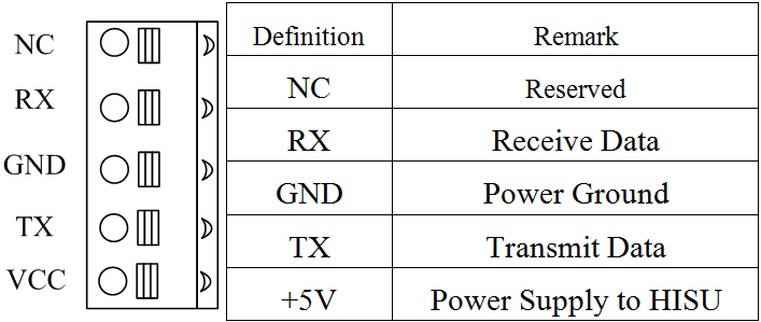

RS232 Communication Connector

|

||||

| Pin | Name | Colors at the beige round cable | Colors at the grey flat cable | Description |

| 1 | NC | - | - | Not Connected |

| 2 | RX | Brown-White | Yellow | RS232 Receive data |

| 3 | GND | Blue | Green | Ground |

| 4 | TX | Blue-White | Red | Transmit data |

| 5 | VCC | - | - | Power Supply 3.3 V to HISU. For PC software use unconnected. |

Note 1: The RS232 communication port is not isolated. Please use an isolated power supply for the iHSV-XX when the PC’s serial port is not isolated.

Note 2: Do not plug or unplug the connector when power is on.

Pulses / Rev. (SW 1-SW 4)

Pulses per revolution of the iHSV57 can be configured via DIP switch S1-S4 or by the tuning software. When all S1-S4 are at “ON” positions, the drive will take the setting set by the software (4000 by default at setting 1:1). In this case, a user can re-configure to any value between 4 and 51200 through software. If any bit of S1-S4 is at “OFF” position, the integrated drive board will take micro step resolution setting determined by bit positions of S1-S4. Use the following table for their resolution settings via the DIP switches.

|

Pulses / Revolution

|

S1

|

S2

|

S3

|

S4

|

|

Software Configured (Default 4000 when Electronic Gear is 1:1)

|

On

|

On

|

On

|

On

|

|

800 |

Off |

On |

On |

On |

|

1600 |

On |

Off |

On |

On |

|

3200 |

Off |

Off |

On |

On |

|

6400 |

On |

On |

Off |

On |

|

12800 |

Off |

On |

Off |

On |

|

25600 |

On |

Off |

Off |

On |

|

51200 |

Off |

Off |

Off |

On |

|

1000 |

On |

On |

On |

Off |

|

2000 |

Off |

On |

On |

Off |

|

4000 |

On |

Off |

On |

Off |

|

5000 |

Off |

Off |

On |

Off |

|

8000 |

On |

On |

Off |

Off |

|

10000 |

Off |

On |

Off |

Off |

|

20000 |

On |

Off |

Off |

Off |

|

40000 |

Off |

Off |

Off |

Off |

Active Edge Setting (S5)

S5 is used for setting the active edge of the input signal, “off” -means the active edge is the rising edge, while “on” is the falling edge.

Motor Shaft Direction (S6)

DIP switch S6 is used for changing motor shaft rotation direction. Changing position from “ON” to “OFF”, or “OFF” to “ON” will reverse rotation direction of the iHSV57-XX.

Already default parameters are set by factory. Those default parameter values have been optimized. They should be good enough for most industrial applications, and there is no need to tune them. However, if you want to fine tune the iHSV-XX for best performance for your applications, the tuning software is offered which allows you to adjust those parameters.

Connection to Common Anode

Connection to Common Cathode

Connection to Differential Signal

Note1: : The RS232 communication port is not isolated. Please use a galvanically isolated power supply for the iSV57 when the PC’s serial port is not isolated.

Note2: Do not plug or unplug the connector when power is on.