Hybrid Servo Driver

CS-D808/ CS-D1008

Digital Technology, max. 80/ 100 VDC, 8.0 A

Download data sheet

Download data sheet Download ProTuner CS-D software

Download ProTuner CS-D software Download user manual

Download user manual  Download software manual

Download software manual Download RS232 pin layout

Download RS232 pin layout

Leadshine CS-D808/ CS-D1008 is a closed-loop stepper motor driver which is designed to solve the problem of step loss in open-loop stepper motor controllers and increasing system reliability with minimal cost.

The CS-D808/ CS-D1008 implements Leadshine's advanced control algorithm based on their ten years of experience in stepper motor and servo control. The CS D808/ CS-D1008 is highly reliable and competitively priced and is ideal for many industrial applications such as CNC, medical, electronics, packaging.

The CS-D808/ CS-D1008 can power 2-phase stepper motors with incremental encoders. Compared to conventional open-loop stepper motor systems, a closed-loop CS-D808/ CS-D1008 can eliminate possible step losses, perform real-time position error correction, and does not require torque reservation (100 % torque implementation). It operates the stepper motor with reduced heating, noise, vibration, etc.

- Closed-loop, eliminates loss of synchronization

- Enhance performance at low speed application ( < 60 RPM)

- No torque reservation required for readjustment control

- No Tuning required for easy commissioning

- Supply voltage CS-D808: 30 - 80 VDC, CS-D1008: 30 - 100 VDC supply voltage,

- Output current of max. 8 A

- Pulse input frequency up to max. 200 kHz

- A configurable digital output for “In Target Position Range” signal, or as brake command signal

- Micro step resolution 15 settings of 800 - 51,200 via DIP switches, or 200 - 51,200 via software (increments of 200)

- Protections for over voltage, over current and position error

|

Parameters

|

Min | Typical. |

Max

|

Unit |

|

Output current

|

0.5

|

-

|

8.0 (Peak)

|

A

|

|

Supply voltage CS-D808

|

+30

|

-

|

+80

|

VDC

|

|

Supply voltage CS-D1008

|

+30

|

-

|

+100

|

VDC

|

|

+20

|

-

|

+80

|

VAC

|

|

|

Logic signal current

|

7

|

10

|

16

|

mA

|

|

Pulse input frequency

|

0

|

-

|

200

|

kHz

|

|

Minimal pulse width

|

2.5

|

-

|

-

|

µs

|

|

Minimal direction setup

|

5.0

|

-

|

-

|

µs

|

|

Insulation resistance

|

500

|

MΩ

|

| Cooling |

Natural cooling or forced air cooling |

|

|

Operating Environment |

Environment |

Avoid dust, oil, fog and corrosive gases |

|

Ambient Temperature |

0 ℃ - 65 ℃ |

|

|

Humidity |

40 % RH - 90 % RH |

|

|

Operating Temperature |

0 - 50 °C |

|

|

Vibration |

10 - 50 Hz/ 0.15 mm |

|

| Storage Temperature |

-20 - 65 °C |

|

| Weight |

Approx. 570 g |

|

|

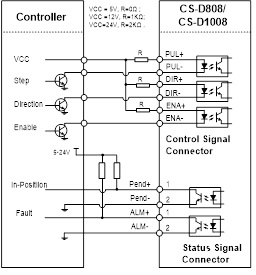

Control Signal Connector |

|||||||||||

|

Name |

I/O |

Description |

|||||||||

|

PUL+ |

I |

Pulse signal: (2) In double pulse control mode (CW/ CCW), set via PC software, this signal input represents a clockwise (CW) pulse and is active at both high voltage level and low voltage level. |

|||||||||

|

PUL- |

I |

||||||||||

|

DIR+ |

I |

Direction Signal: |

|||||||||

|

DIR- |

I |

||||||||||

|

ENA+ |

I |

Enable signal: This signal is used for enabling/disabling the driver. High voltage level of 4.5 - 24 V (NPN control signal) for enabling the drive and low voltage level of 0 - 0.5 VDC for disabling the driver). On the contrary please note that that PNP and Differential control signals with low voltage enable the drivers. By default, this signal is left UNCONNECTED & ENABLED. |

|||||||||

|

ENA- |

I |

||||||||||

|

Signal Connector |

|||||||||||

|

Name |

I/O |

Description |

|||||||||

|

Pend+ |

O |

Configurable Digital Output Signal: |

|||||||||

|

Pend- |

O |

||||||||||

|

ALM+ |

O |

Fault Signal: |

|||||||||

|

ALM- |

O |

||||||||||

|

Encoder Feedback Connector |

|||||||||||

|

Name |

I/O |

Description |

|||||||||

|

EB+ |

I |

Encoder channel B+ input |

|||||||||

|

EB- |

I |

Encoder channel B- input |

|||||||||

|

EA+ |

I |

Encoder channel A+ input |

|||||||||

|

EA- |

I |

Encoder channel A- input |

|||||||||

|

VCC |

O |

Encoder +5 V voltage output connection |

|||||||||

|

EGND |

GND |

Power ground connection |

|||||||||

|

Encoder Extension Cable Wire Out |

|||||||||||

|

Wire |

Color |

Name |

Description |

Wire |

Color |

Name |

Description |

||||

|

1 |

Red |

VCC |

+5 V power input |

4 |

Blue |

EA- |

Encoder Channel A- |

||||

|

2 |

White |

GND |

GND |

5 |

Yellow |

EB+ |

Encoder Channel B+ |

||||

|

3 |

Black |

EA+ |

Encoder Channel A+ |

6 |

Green |

EB- |

Encoder Channel B- |

||||

Notes:

(1) Shielding control signal wires are suggested

(2) to avoid/ reduce interference, do not tie control signal cables and power wires together

|

Power and Motor Connector |

||||

|

Pin Name |

I/O |

CS-D808 Description |

||

|

A+ |

O |

Stepper motor A+ connection Connect motor A+ wire to this pin |

||

|

A- |

O |

Stepper motor A- connection Connect motor A- wire to this pin |

||

|

B+ |

O |

Stepper motor B+ connection Connect motor B+ wire to this pin |

||

|

B- |

O |

Stepper motor B- connection Connect motor B- wire to this pin |

||

|

+V |

I |

Power supply positive connection 30 – 80 VDC power supply voltage |

||

|

GND |

GND |

Power supply ground connection |

||

|

|

|

CS-D1008 Description |

||

|

A+ |

O |

Stepper motor A+ connection Connect motor A+ wire to this pin |

||

|

A- |

O |

Stepper motor A- connection Connect motor A- wire to this pin |

||

|

B+ |

O |

Stepper motor B+ connection Connect motor B+ wire to this pin |

||

|

B- |

O |

Stepper motor B- connection Connect motor B- wire to this pin |

||

|

AC |

I |

Power supply connection |

||

|

AC |

I |

|||

|

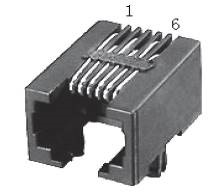

RS232 Communication Port |

||||

|

Pin |

Name |

I/O |

Description |

|

|

1 |

NC |

- |

Not connected |

|

|

2 |

+5V |

O |

+5 V power output |

|

|

3 |

TxD |

O |

RS232 transmit |

|

|

4 |

GND |

GND |

Ground |

|

|

5 |

RxD |

I |

RS232 receive |

|

|

6 |

NC |

- |

Not connected |

|

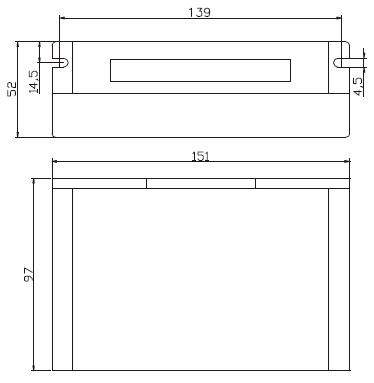

(unit: mm)

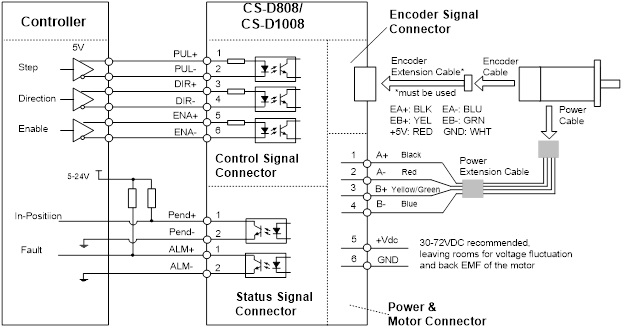

A complete closed loop stepper system should include a stepper motor with encoder, CS-D808/ CS-D1008 driver, power supply and controller (pulse generator). A typical connection is illustrated.

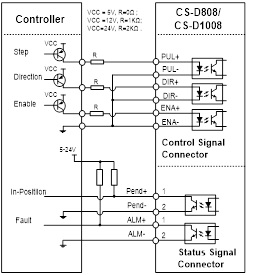

The CS-D808/ CS-D1008 can accept differential and single-ended control signal inputs (open-collector and PNP output). A CS D808/ CS-D1008 has 3 optically isolated control inputs, PUL, DIR, and ENA. Refer to the following two figures for connections of open-collector and PNP signals.

Connection to Common Cathode |

Connection to Common Cathode |