MX3660 3-Axis Stepper Drive

3-Axis DSP Based Digital Stepper Drive Max 60 VDC / 6.0A

Download datasheet

Download datasheet

Download datasheet (Leadshine)

Download datasheet (Leadshine) Download driver software

Download driver software

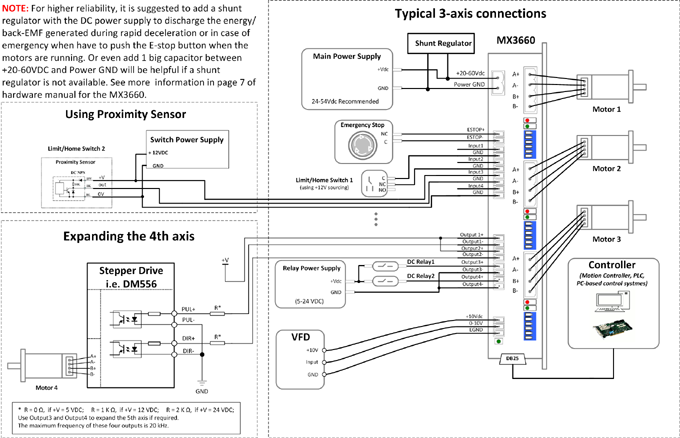

Hardware Installation Manual for MX3660.

Hardware Installation Manual for MX3660.

The Leadshine MX3660 is a high performance 3-axis stepper drive with built-in breakout board and I/O’s based on the latest DSP technology. It is specially designed for EASY and RAPID control of up to three 2-phase (1.8°) in frame sizes NEMA 17, 23, and 24. The MX3660 3-axis stepper drive operates under 20-60 VDC input voltage and can output up to 6.0A current (peak of sinusoidal) per axis. It takes step & direction control and is easy to implement for OEM applications.

By adopting Leadshine advanced stepper motor control technology, the MX3660 3-axis stepper drive can power stepper motors in high precision, at extra smoothness, and with extra low motor heating & noise. It is featured with anti resonance, multi-stepping, vibration suppression, input command smoothing, 50% idle current reduction, etc.

The MX3660 3-axis stepper drive is easy to configure. Via the 6-pin DIP switch of each of the 3 stepper drive modules, a user can easily set the output current and micro step to one of their 8 available settings, 1.45-6.0A and full step - 1/64 respectively. Each axis can have its own current & micro step configurations to satisfy different requirements for the controlled stepper motor. For example, a user can set axis X at 8 micro steps & 6.0A for a NEMA 34 motor, axis Y at 10 micro steps & 4.25 A for a NEMA 24 motor, and axis Z at 16 micro steps & 1.41A to for a NEMA 17 motor.

The MX3660 3-axis stepper drive is integrated with a breakout board with a DB25 connector and built-in I/O’s. This allows convenient, easy and quick connection for controllers (e.g. PC-based control systems, motion controllers, PLC’s…) and external devices (limit switches, VFD…). It simplifies system setup, save installation space & time, minimize wiring, increase reliability, and cut costs. In addition, the MX3660 offers a built-in digital “smoother” to allow filtering/smoothing of "noise" pulses for better system performance (application dependant).

- Power up to 3 stepper motors of NEMA 17, 23, 24

- Option to 4th axis

- Sophisticated stepper motor control based on the latest DSP technology

- Built-in breakout board and I/O’s

- Step & direction Control

- 200 KHz maximum frequency for each axis

- 20 - 60 VDC supply voltage

- 1.41 - 6.0A output current per axis

- 8 micro step settings: 1, 1/2, 1/4, 1/8, 1/10, 1/16, 1/32, 1/64

- 8 output current settings of 1.41 - 6.0A for each axis

- Damping and anti resonance

- Allowing individual output current & micro step settings for each axis

- Input pulse smoothing for less jittering, higher torque, and quicker response

- Extra low motor heating & noise

- Extra smooth motor movement

- Simple micro step & output current configuration via DIP switches

- Fault output

- 50% automatic idle current reduction

| Parameters | Min | Typ. | Max | Unit |

| Input Voltage | 20 | 48 | 60 | VDC |

| Continuous Current | 0 | - | 6.0 (peak) | A |

| Pulse Input Frequency | 0 | - | 200 | kHz |

| Pulse Voltage | 0 | 5 | 5 | V |

| Logic Signal Current | 7 | 10 | 16 | mA |

| Isolation Resistance | 100 | 0 | 0 | Ω |

| Parameters | Values. |

| Input Voltage | 20-60VDC |

| ESTOP, Input1, Input2, Input3, Input4 | Optical Isolation,12V Source,10mA MAX |

| Output1, Output2, Output3, Output4 | Optical Isolation, 24V, 70mA MAX |

| 0-10V Analog Output | 0.9 to 8.9V, 20mA MAX |

With integrated breakout boards and built-in IO’s, Leadshine MX3660 3-axis stepper drives can be easily implemented as general purpose stepper drives to power 3 two-phase stepper motors in frame size 17, 23, 24, and 34. They are ideal solutions to many applications with 2-3 axis stepper systems such as CNC machinery, electronics, semiconductors, medical, packaging, lab automation, etc. They can be easily adopted in stepper control systems for machines like CNC routers / engravers, light-duty CNC mills, CNC lathes / Cutters, laser cutters / markers / engravers, CNC welders, waterjet cutters, X-Y tables, CNC dispensing machines, medical equipments… The unique design of MX3660 with DB25 connectors makes it fit seamlessly with many popular CNC control systems like Mach3 and EMC.

A typical system consists of stepper motor, stepper motor driver, power supply and controller. The following image shows a typical connection schematic: