Minimal Quantity Lubrication BPV-225

Download data sheet

Download data sheet

The Minimal Quantity Lubrication System or Minimal Quantity Cooling Lubrication System works according to the Venturi effect. It brings small amounts of lubricant directly to the tool/workpiece area to reduce the generation of frictional heat in machining. In addition, a cooling effect occurs caused by the carried air and when using volatile lubricants such as alcohol by evaporative heat loss.

The Minimal Quantity Lubrication BPV-225 can be used with thin oils, alcohols and water-oil emulsions.

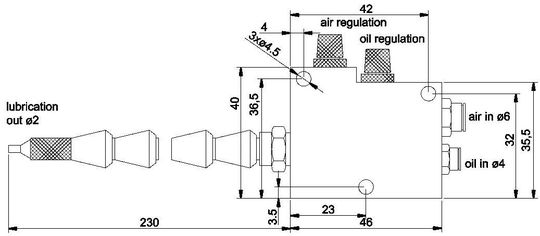

The supply of lubricant and air can be set optimally with the two control screws, depending on lubricants, materials and purposes.

By using the Minimal Quantity Lubrication, the lifetime of the tool can be substantially increased and the quality of the machined surface can be significantly improved.

- 1× Minimal Quantity Lubrication BPV-225 with a flexible gooseneck, length approx. 230 mm

- 1× lubricant feeding tube with filter and non-return valve, length approx. 3 m