Product finder

| 0800-010-0001 | SV230V AC 2V025-08 Solenoid Valve | Data sheet | Details | |||||||

Description:Direct acting 2/2-Way solenoid valve, normally closed, no minimum pressure required, connections with female thread G1/4-19“, complete with push-in fittings for 6 mm hose, for 230 V AC operation, fully assembled.

|

||||||||||

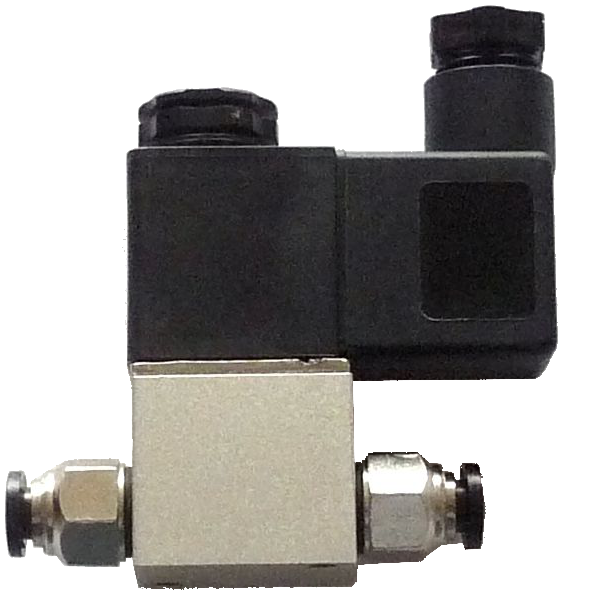

| 0800-010-0003 | SV24V DC 2V025-06 Solenoid Valve | Data sheet | Details | |||||||

Description:Direct acting 2-Way solenoid valve, normally closed, no minimum pressure required, connections with female thread G 1/8-28“, complete with push-in fittings for 6 mm hose, for 24 V DC operation, fully assembled.

|

||||||||||

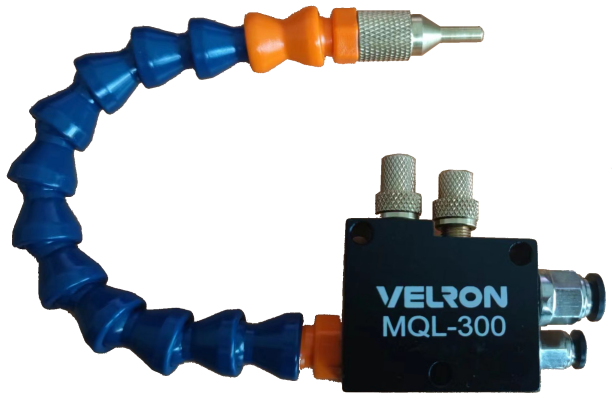

| 0900-010-0005 | MQL-300 Minimum Quantity Lubrication | Data sheet | Details | |||||||

Description:

The Minimal Quantity Lubrication System or Minimal Quantity Cooling Lubrication System works according to the Venturi effect. It brings small amounts of lubricant directly to the tool/workpiece area to reduce the generation of frictional heat in machining. In addition, a cooling effect occurs caused by the carried air and when using volatile lubricants such as alcohol by evaporative heat loss.

|

||||||||||

EN

EN

DE

DE